Client: National Oil Company

Location: Asia Pacific

Challenge:

The Client recognised a recurring trend of stuck pipe events offshore and was in search of a solution which would mitigate these costly stuck pipe incidents and reduce the associated non-productive time (NPT).

Solution:

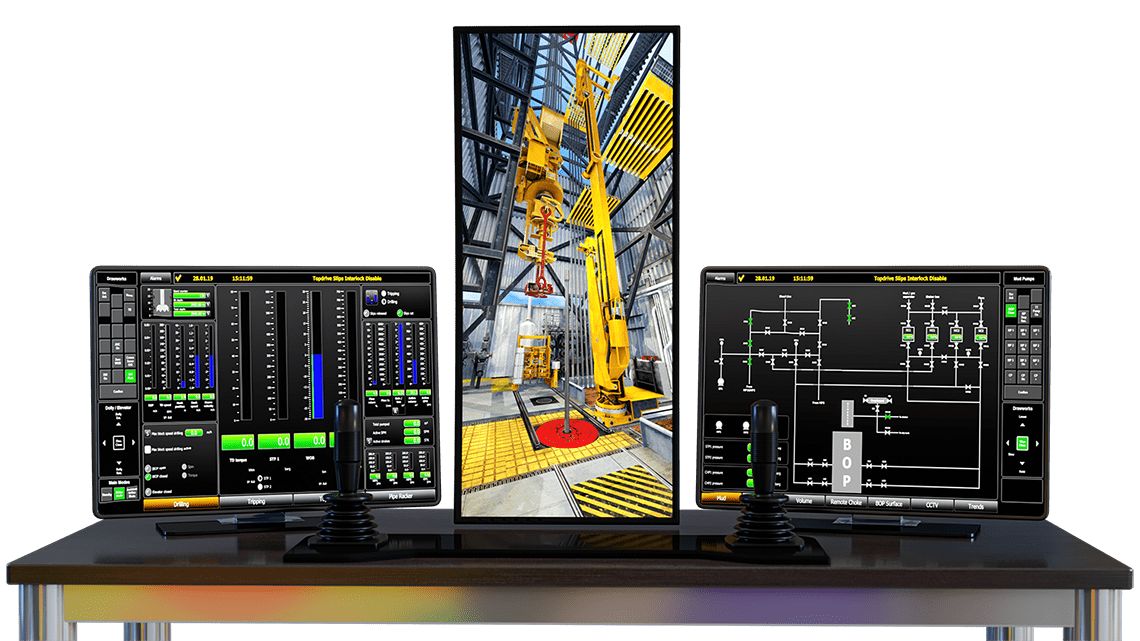

We provided a learning solution combined with practical simulation to help prepare the client’s wellsite drilling team and their drilling contractor as part of a cohesive intercompany crew training event. A portable simulator was used to create a digital twin of the well’s subsurface conditions to train the team in stuck pipe freeing and recovery operations. Our in-house programming team, supported by our customer service and technical teams, ensured this bespoke programme was prepared and delivered within a short lead-time.

Aberdeen Drilling International has been working closely with this NOC since we began operating in Malaysia. The client requested a Stuck Pipe Prevention (SPP) course that included simulation after several recent and recurring stuck pipe events. Their goal was for the crews to correctly apply first actions to free the pipe and mitigate the root causes of stuck pipe. Following discussions with the client, we prepared a digital well twin for practical simulation and Well Operations Crew Resource Management (WOCRM) for both the operator’s and the contractor’s wellsite teams. The ADS1-DRILL portable simulator was used to create the well’s digital twin for practising early detection, first actions for freeing pipe and stuck pipe mitigation processes. This proved vital for the crews to lower the incidence rate and therefore reduce the NPT.

Using the ADS1-DRILL portable simulator, we provided this training on board the client’s operational rigs, according to the risk of stuck pipe and the operations schedule of each rig. By utilising the ADS1-DRILL simulator, we were able to provide a precise digital twin using the client’s well data. Our highly experienced rigsite coaches used the digital well twins to modify the SPP procedures for each well in the client’s drilling programme.

Following an initial classroom-based SPP refresher, the wellsite teams spent several days immersed in intensive, interactive simulation training exercises. Drilling the Well on Simulator (DWOS) pre-spud preparations on our full-size drilling simulator, in our Kuala Lumpur training centre, included real-time challenges and incident scenarios, sudden changes in well pressures, and fluctuating annulus cuttings loads. These different scenarios allowed the teams to practice their first action responses and rehearse mitigating actions.

The NOC client was particularly pleased with the technical solutions provided by the new simulators, especially the downhole hydraulic and jarring models. Course participants were engaged with bespoke simulator-based training which focused on best practices in stuck pipe prevention, and addressed many of the operational challenges faced by our client’s operations teams.

“The simulator helps the crew to become familiar with stuck pipe indications and mechanisms based on the observed parameters […] providing them opportunities to “fire up” the thought process on stuck pipe events, from early warning signs to the determination of the stuck pipe mechanism to the first actions to take in the event of being stuck.” – Night Drilling Supervisor